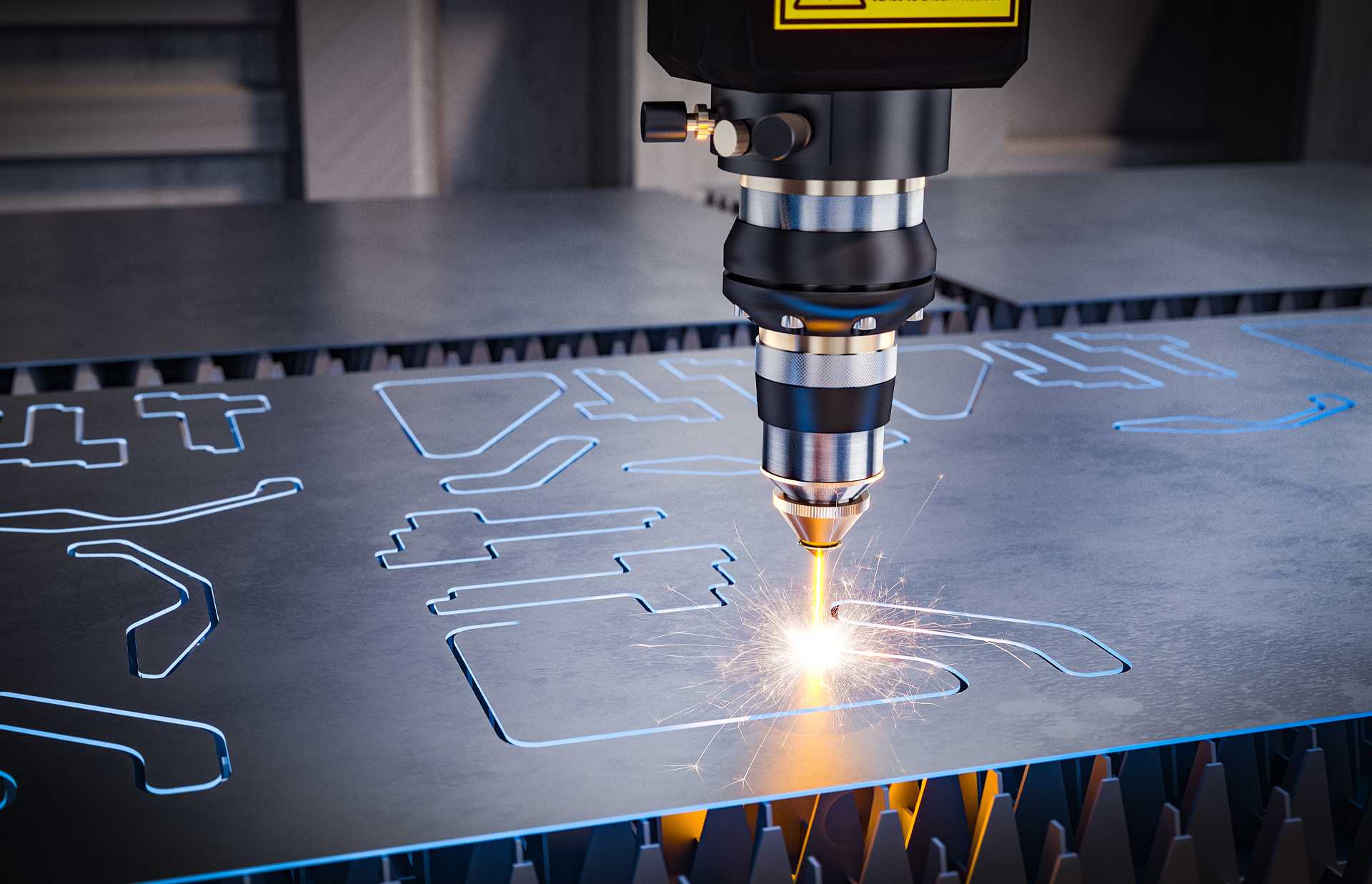

When precision and accuracy are non-negotiable, Cordeck delivers.

Our advanced laser cutting services achieve tighter tolerances and intricate designs that fit perfectly the first time, eliminating costly rework in most fabrications. By leveraging a focused laser beam, we can deliver parts and components that meet even the most complex specifications, from prototypes to full-scale production runs.

In today’s fast-paced construction and manufacturing environments, speed matters. Cordeck’s laser cutting services are engineered for efficiency, providing rapid processing times without compromising quality. Whether your project involves intricate geometries or high-volume output, we deliver quick turnarounds to keep your timelines on track, even under the tightest deadlines.

We understand that no two projects are alike. That’s why we offer flexibility across a wide range of materials, including steel, brass, copper, stainless steel, and more. Our laser cutting technology allows for custom shapes, intricate patterns, and versatile part designs, giving your team the ability to create unique solutions. From one-off prototypes to production, we scale to meet your needs.

The precision of Cordeck’s laser cutting means a narrow kerf width and cleaner cuts, maximizing material yield and reducing waste. With less finishing work required after production, our services lower overall fabrication costs while delivering high-quality results.

While multiple cutting methods exist, laser cutting often delivers the most balanced combination of precision, versatility, and speed. Compared to EDM, which is slower for high-volume runs, laser cutting provides equal accuracy at a fraction of the time. Plasma cutting may work for heavy plate cutting, but it produces rougher edges that require extra finishing. Laser cutting achieves superior surface quality upfront. And while waterjet handles ultra-thick or non-metal substrates, it is slower and less precise than laser cutting for most metals and intricate designs.

Every part we produce adheres to strict quality control standards. Our team of engineers, project managers, and skilled technicians ensures every cut is precise and every order meets specifications. Fully American-made: harvested, melted, milled, and manufactured using US-mill-certified steel.

Since 1994, we have been manufacturing corrugated metal decking, steel deck accessories, in-floor cellular raceway systems, and offering precision laser cutting services. We proudly deliver high-quality metal decking and accessories across the United States from our eight strategically located facilities.

When deadlines are tight and accuracy is critical, trust Cordeck to deliver flawless results.

Call a Dexpert® today at 877-857-6400 or send us an email at [email protected] to review your next project and experience the Cordeck difference.